The two most commonly used technologies in custom printing are sublimation and screen printing and despite having their own characteristics and applications. It is therefore important to understand the differences between these methods when determining which process to follow in an organization or when they are required by an individual.

This article will examine the distinctions between sublimation and screen printing and how they work, what advantages and disadvantages they have, and what kinds of uses they are best suited for.

All About Screen Printing

Screen printing also referred to as silk screen or serigraphy is a printing technique whereby certain portions of a screen are blocked using a stencil in order to transfer ink on to the substrate. It can be used on fabrics and paper and it can also be used on glass, ceramics, metals and plastics.

Materials for Screen Printing

- Screen print

- Stencil

- Squeegee

- Substrate: The material to be printed on (e.g., fabric, paper, glass).

- Printing Press: Devices for supporting the screen and the substrate.

- Screen Printing Ink: There are different types of inks used in screen printing, depending on the substrate and the appearance that is required. Most of the inks are as follows: Plastisol Ink, Water-Based Ink, Discharge Ink and Solvent-Based Ink

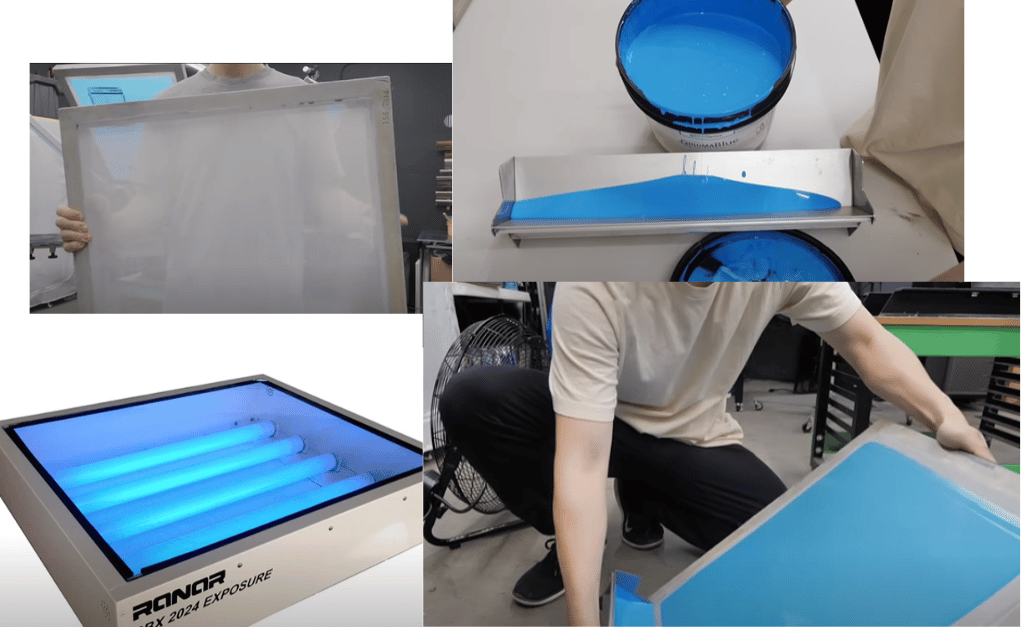

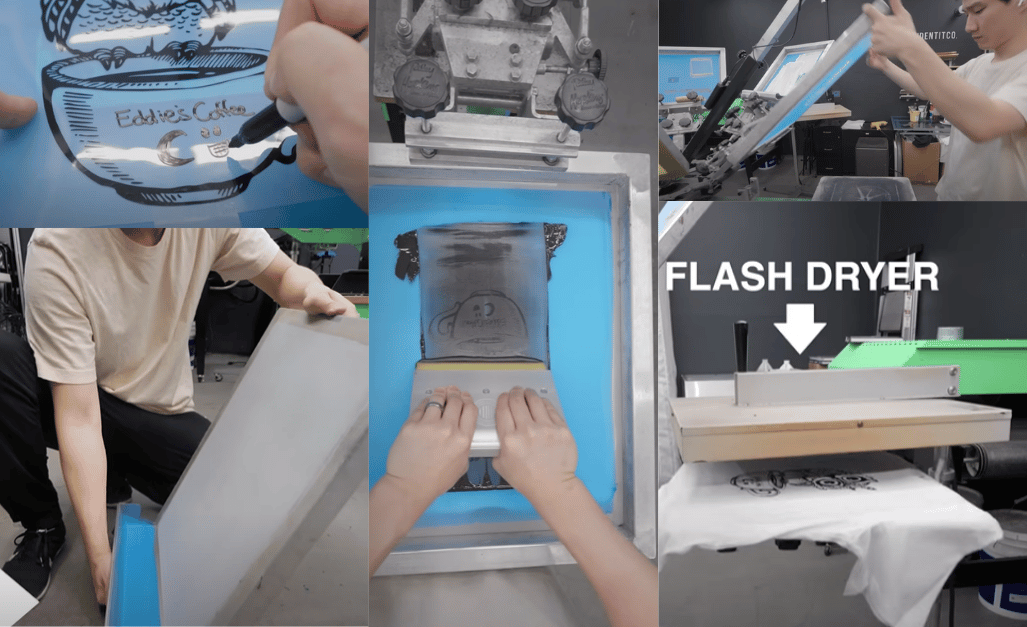

Screen Printing Process

- The process begins by creating the design to be printed, which is then transferred into stencils or film.

- The mesh screen that has a light-sensitive emulsion is placed over a film positive and exposed to UV light, which solidifies the emulsion and forms a stencil.

- Setting up the screen with the substrate (t-shirt or poster) under the screen.

- Place the ink on the screen and with the squeegee, apply the ink on the stencil.

- After the printing, the ink used dries or cures up. This is done through heat, UV light, or air drying, depending on the type of ink used.

- It is only when the ink is dry that the printed item is checked, and all the final touches are given.

Screen Printing Applications

Although screen-printing is mostly used in making shirts, it can be applied to many other products and events. Here are some examples.

- Apparel: T-shirts, sweatshirts, hoodies, and other similar clothing items.

- Promotional products, such as mugs and tote bags.

- Sports Gear: Uniforms such as team jerseys in bulk are popular.

- Banners and Signs: posters, banners, and signs that are both indoor and outdoor.

Screen Printing Methods

Let’s explore the different methods of screen printing:

- Traditional Screen Printing: Manual or mechanical screen printing is the oldest and most common form of screen printing, commonly referred to as traditional screen printing. This technique entails the preparation of detailed screen print stencil (or screen) to be used to apply multiple layers of ink on the printing surface.

- Automatic Screen Printing: This is also known as mechanical screen printing, where the printing process is done using machines as opposed to manual methods. This method proves to be highly effective when the production run is large.

- Rotary Screen Printing: Rotary screen printing is a high-speed and continuous process using rotary screens to print on roll-to-roll substrates. It is widely utilized in the processes of printing textiles and wallpapers.

- Flatbed Screen Printing: This technique employs a flat screen and flat printing plane; hence, it is applicable for rigid materials such as glass, wood, and plastic, among others. This subject is famous for its accuracy and effectiveness in dealing with thick layers of ink.

- UV Screen Printing: Screen printing employs UV inks that dry immediately using ultraviolet light. This is useful for printing on non-porous materials, and its advantage is that the prints are very hard-wearing.

Advantages of Screen Printing

Screen printing offers a wide range of benefits.

A. Versatility

It is a versatile process in terms of the compatibility of materials used and allows for a number of print types, including ink, making it ideal for applications such as clothing, posters, packaging, and electronics.

B. Cost-Effectiveness for Large-Run

Screen printing is ideal for large orders to an extent since the initial costs of designing a screen are lower with the increasing order quantity.

Durability and Longevity:

Screen printing is ideal for large orders to an extent since the initial costs of designing a screen are lower with the increasing order quantity.

Disadvantages of Screen Printing

Here are the following drawbacks of screen printing:

A. Limited Color Range:

Multi-colored networks may be suboptimal because of color limitations and requiring different screens, which can lead to higher time and costs, and color matching may be highly difficult and expensive.

B. Environmental Concerns:

Screen printing produces a lot of waste in the form of ink, screens, and cleaning fluids, which call for disposal and recycling systems to prevent pollution. There must be approaches to reduce the negative effects of the environment.

Traditional screen printing inks and cleaning products may include hazardous substances which may be a threat to the health of humans and the environment and therefore should be handled and disposed properly.

All About Sublimation Prints

Sublimation printing is an industry of printing that incorporates heat to transfer dye into substrates including fabrics, plastics, and ceramic surfaces which have been coated. It produces high quality prints with full color and durability and is usually associated with high costs.

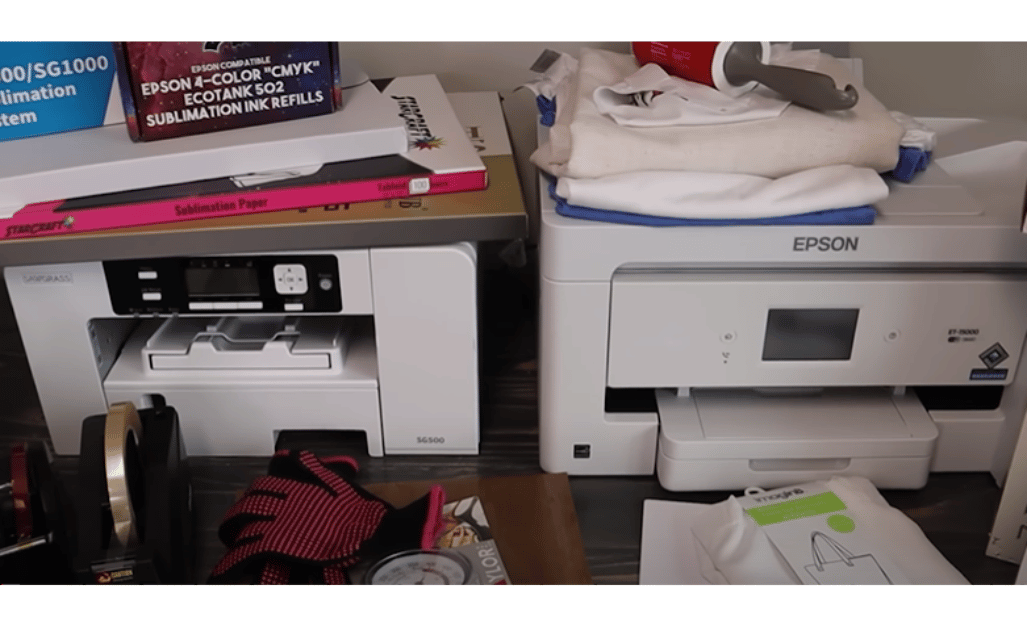

Materials Used in Sublimation printing

- Sublimation Printer

- Sublimation Ink cartridges

- Sublimation Paper

- Substrates

- Heat Tape

- Protective Pape

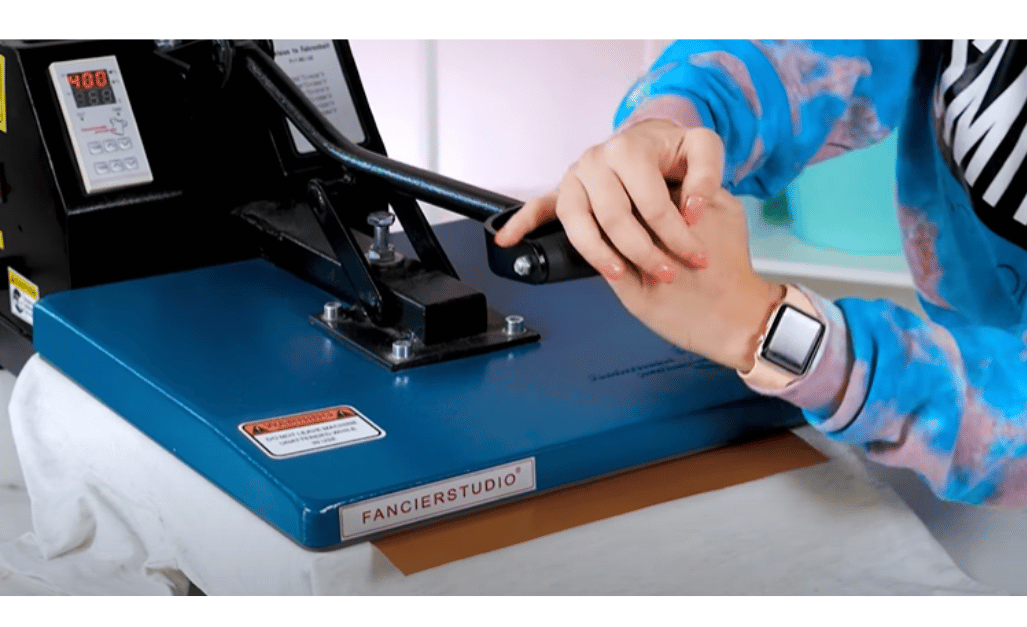

- Heat Press

Sublimation Printing Process

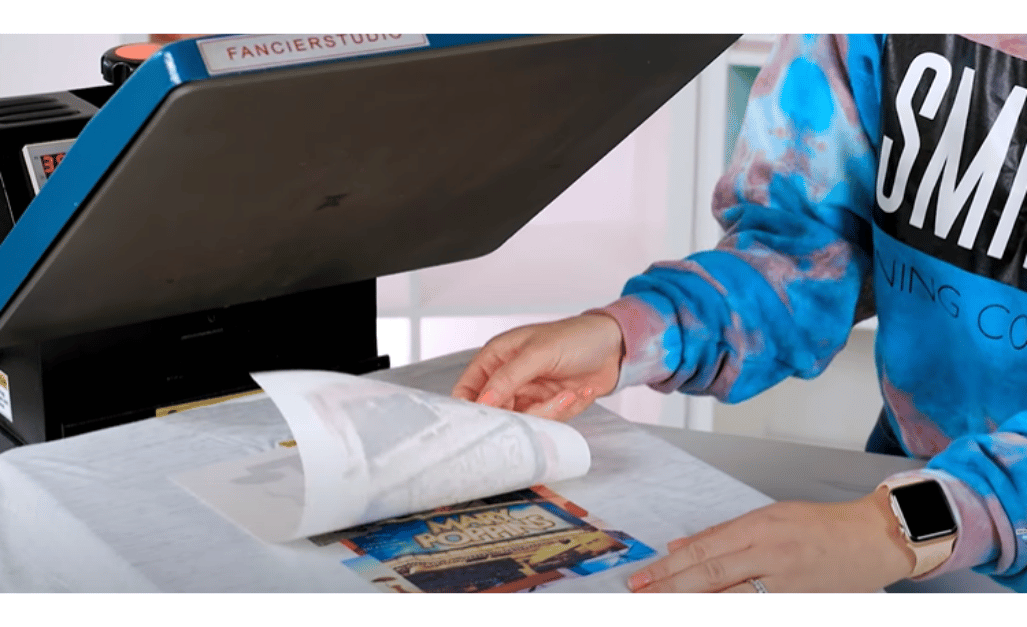

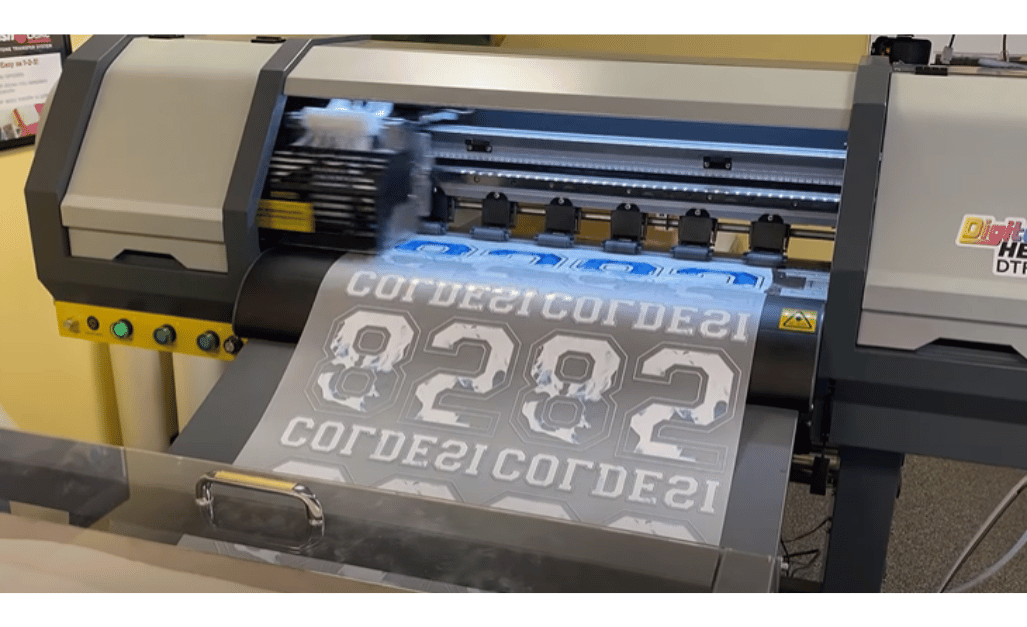

- Sublimation inks are used to print the design on transfer paper

- Then, you transfer the paper on a product and iron it using a heat press.

- Heat makes the inks evaporate and the material receives them.

- As a result, this offers a permanent and lively print that remains bright and intact without fading or peeling.

Sublimation Print Applications

This is a digital printing method that is applied to any material that can support custom-printed designs. Such as:

- Apparel and Accessories. Shirts, hooded tops, trousers, skirts, stockings, neckties, scarves, and much more.

- Gaming or workplace accessories. For instance, mouse pads and desk mats.

- Home Decor. Including, but not limited to, customized curtains, rugs, pillows, blankets, and others.

- Promotional Products. Such as mugs, phone cases, and tote bags.

- Sports Gear. Cool products: uniforms, fan merchandise, jerseys and many others.

- Wall Art. These are posters, canvases, sigils, banners, and any other type of print.

Sublimation Printing Methods

There are different methods of sublimation printing that can be used, depending on the substrate as well as the required end result. Here are some common methods:

- Garment Sublimation: Clothing dye sublimation is a common method used in the fashion industry for creating clothing products. This approach proves suitable for white or very light-colored polyester because sublimation dye couples with polyester well. Sublimation can be done for many apparel items, such as T-shirts, sportswear, and promotional apparel.

- Sublimation on Hard Substrates: However, sublimation is not restricted to fabrics; rather, it can be used on mugs, phone cases, metal sheets, and many more stiff items. These items require a polyester coating for sublimation ink to be accepted into the material.

- All-Over Sublimation: The idea of all-over printing is perfect for utilizing entire items and is beneficial for garments. This method is most commonly used for such applications as developing vivid and memorable sportswear, shirts, jerseys, and fashionable clothing, for example.

Advantages of Sublimation Printing

There are numerous benefits of sublimation printing;

A. High-Quality, Vibrant Prints

The other major advantage that comes with sublimation printing is that it has the ability to produce highly visible prints. It also allows for full-color printing that is detailed, useful for designs with many colours or many details like a pattern.

B. Uses Safe Ink And Less Water

Compared to other forms of printing, such as screen printing, sublimation is considered to be more environmentally friendly. The process uses water soluble dyes without the formation of any poisonous chemical compounds, and since no screen or stencil is used, the waste produced is very minimal.

Disadvantages of Sublimation Prints

Here are the following drawbacks of sublimation printing:

A. Material Limitations

Another disadvantage of sublimation printing is the fact that it can only be used on a limited type of material. It is most effective on polyester or polymer-coated base materials. It impacts the prints in such a way that substrates such as natural fibers, for instance, cotton, will not properly absorb the dye, hence making the prints less durable and less bright.

B. Cost of Equipment

The first step of using sublimation printing could be a little bit expensive. Sublimation printers and heat presses can be pricey, which can be costly for small businesses or people who only use it occasionally. However, they may also be more expensive compared to the other inks that are used in the printing process.

C. Risk of Color Fading Under UV Light

However, despite the high durability of sublimation prints, they are not immune to the effects of UV rays. These colors may also fade away with time if the cloth is left out in the sun for a long time. This makes sublimation prints less ideal for outdoor purposes unless measures against UV light are put in place.

Screen Print vs. Sublimation: Deep Comparison

To assist you in arriving at a suitable decision, let’s discuss screen printing and sublimation printing based on several criteria.

A. Number of Colors

Screen Printing: This is because the screen printing technique is preferable for works of art with few colors since it becomes cumbersome and expensive to add more colors.

Sublimation Printing: Sublimation printing is a digital process that allows for full-color prints without additional costs or complexity of setup and is suitable for bright, many-shaded prints.

B. Print Quality

Ink is used in screen printing techniques to print very bright and opaque colors on black fabrics, and the print looks brilliant and lasts for a long time.

Sublimation Printing: The sublimation printing process yields high-quality prints and is known for its finely-detailed color reproduction. The ink penetrates through the fabric and settles on its surface, thus providing a smooth, long-lasting, and highly durable print.

C. Print Complexity

Screen Printing: Some designs, such as those with gradients or elaborate patterns, may not be suitable for screen printing because it is a layering process that relies on screens.

Sublimation printing: This is so because sublimation printing does not pose any difficulty in the production of gradients, fine lines, or even photorealistic images.

D. Cost-Effective Method

Screen printing is cheaper than other methods of printing and is ideal for printing large quantities of products with simple prints and limited colors.

Sublimation printing is also ideal for small to medium orders, especially when multiple colors are involved, as it does not add extra charges for a variety of colors.

E. Maintain Quality of Fabrics

Screen printing has developed modern inks and methodologies that have enhanced the feel of fabric through screen printing, particularly when thick layers of ink are incorporated.

Sublimation printing is a technique in which the ink is infused into the fabric to make the cloth softer and more breathable than it originally was.

F. Printing Methods

Screen printing deals with the preparation of a screen, then using the screen to spread ink over fabric.

Sublimation printing works, heat transfer printing dyes materials, prints designs on a sublimation paper, and then heat presses on fabrics.

G. Color Blending

An issue that arises when using screen printing is the integration of color blends and gradients, especially with the layered method.

This method is suitable for color mixing, which helps in creating smooth shade transitions and gradients.

H. Photo-Realistic Prints

Screen printing is not very effective when it comes to producing photo-realistic prints because, in most cases, the colors cannot be blended and details cannot be reproduced.

Sublimation printing is one of the most convenient methods of achieving fine, detailed photorealism; therefore, it is the most commonly used when creating detailed images.

I. Digital Prints

Screen Printing: Digital screen printing is also a good option for screen printing but is not as prevalent because the method is costly and slightly more complicated.

This sublimation printing method is a digital one that enables the simple reversal of a digital work and also the reproduction of its designs.

J. Material

Screen printing is a very flexible technique that can be used on a number of fabrics, such as cotton, polyester, and mixed fabrics, but it is perfect for natural fabrics.

It is vital to note that sublimation printing is optimal for polyester fabrics and polymer-coated materials but is not compatible with natural fibers such as cotton.

K. Costly Printers

Equipment for screen printing, including the manual ones, is not very expensive, but when it comes to the automated ones, the prices can be steep.

Sublimation printing needs a good and expensive heat press as well as printer equipment for the best printing production, although the printers are so expensive.

L. Time-Consuming

Screen printing setup is relatively lengthy since screens need to be made for each color; however, for large orders, this method is rather fast.

The use of digital design and printing, which is incorporated in sublimation printing, makes it easier to set up compared to screen printing, but it might take more time to produce individual pieces as compared to screen printing.

Choosing the Right Method

There are several factors to consider when choosing between sublimation and screen printing: the type of material that will be used, the density of the design, the number of pieces to be printed, and the cost. Sublimation is the most preferred printing method, as are other printing methods, for businesses and individuals looking for high-quality and long-lasting print on polyester materials. In contrast, the screen printing technique is more flexible and economically viable for larger-quantity production and a broader range of substrates.

FAQs

Conclusion

Sublimation and screen printing are both great techniques, but they are best for specific purposes. Identifying the advantages and disadvantages and comparing the different parameters of each method will allow you to determine which of the methods is most suitable for use in a specific situation and guarantee that the result is satisfactory. When it comes to creating custom t-shirts, branded merchandise, or any other printed material, deciding on the most suitable printing method for your project is the most crucial decision.